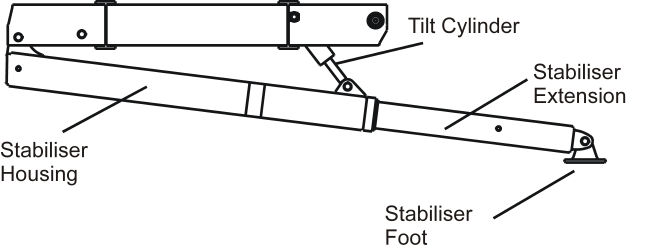

The high stabiliser leg is fabricated box section constructed from medium tensile steel (Grade 350 MPa). The low crane legs are also made from 350 Grade box section. The pins are fitted in glacier bearings that provide reliable and sound mounting of the stabilisers. The versatility of the Steelbro Sidelifter stabiliser legs greatly assists the transfer of containers to or from other vehicles. By being able to extend the leg, then tilt the leg, or tilt the leg, then extend the leg, gives the operator several options.

|

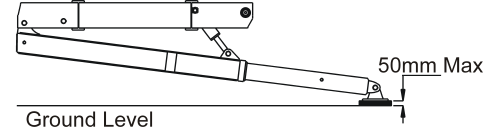

If the stabiliser foot is placed into a hollow or on a descending slope. In such cases it is necessary to build up the ground level by placing timber (dunnage) under the relevant stabiliser foot to restore full lifting capability. Failure to do this can result in damage to the cranes |

|

Take care when placing dunnage under the low crane stabiliser foot. The tilt cylinder should be extended as far as possible in order to limit the induced loads on it. The recommended maximum thickness of dunnage is 50mm. More than 50mm may damage the cylinder. |

|

NEVER under ANY circumstances, operate the Sidelifter WITHOUT first deploying the STABILISERS.

|