S0016 PDF File |

Version 1 |

Structural |

22 Mar 04 |

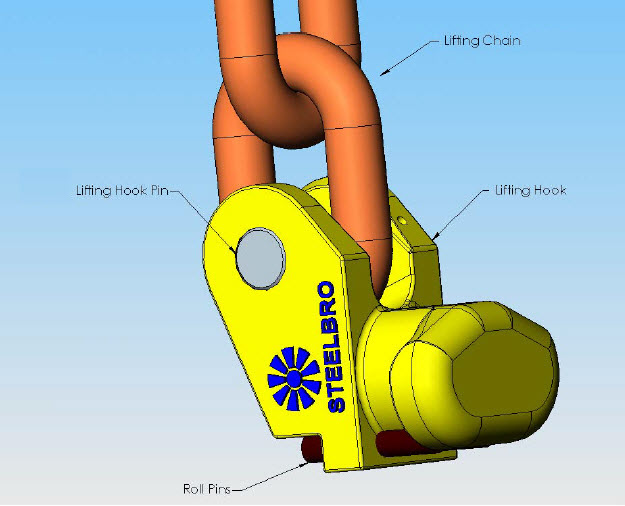

Les tenons de levage consistent en 4 composants principaux comme montre le schéma 1.0.

Figure 1.0: Tenon de levage 3 composants.

La chaîne est fabriquée avec de l'acier endurci et trempé pour répondre aux exigences critiques de cette catégorie et a une haute résistance aux impacts et à l'usure. On peut allonger la durée de vie des chaînes Steelbro en suivant les recommendations suivantes:

Il est important d'inspecter la chaîne régulièrement. Les inspections devraient inclure les éléments suivants:

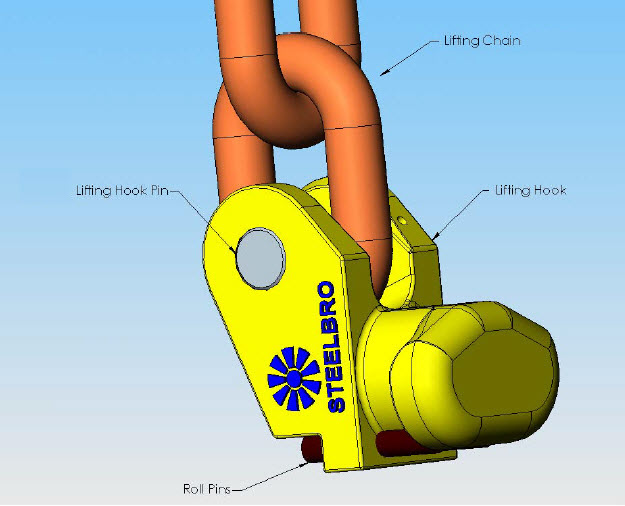

Inspecter chaque maillon individuellement pour voir les signes d'usure, torsion, étirement, entaille ou trou.

|

Minimum Permissible Diameters |

|

Chain Size (mm) |

Crown (mm) |

Elsewhere (mm) |

10.0 |

8.0 |

8.5 |

13.0 |

10.2 |

10.8 |

16.0 |

12.8 |

13.6 |

20.0 |

16.0 |

17.0 |

|

Minimum Permissible Diameters |

|

Chain Size (mm) |

Crown (mm) |

Elsewhere (mm) |

10.0 |

9.0 |

9.0 |

13.0 |

11.7 |

11.7 |

16.0 |

14.4 |

14.4 |

20.0 |

18.0 |

18.0 |

|

Minimum Permissible Diameters |

|

Chain Size (mm) |

Crown (mm) |

Elsewhere (mm) |

16.0 |

14.4 |

14.4 |

20.0 |

18.0 |

18.0 |

Figure 2.0: Chain illustration showing crown

The lifting hook pins are an alloy steel, which is heat treated to produce a high strength material. These pins are strong but not malleable and will not tolerate large amounts of deflection. The pins should not freely rotate due to the roll pin locking mechanism used however the chain should be free to move around the pin.

Safe use of these pins, requires regular inspections of the pins. Inspections that are required are as follows:

Pin Wear Allowance:

Pin diameter (mm) |

Minimum permissible diameter (mm) |

22 |

21 |

If pin wear exceeds the specified allowance then pin must be replaced.

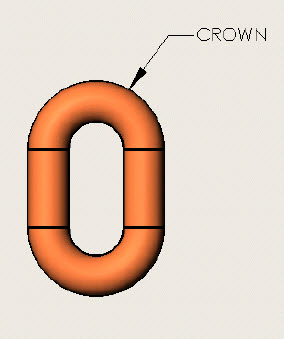

The lifting hook is cast from high-grade steel. The lifting hook has 4 main parts, which are; the clevis ears, the shaft, the shaft ears and the body. They are shown in figure 3.0 below. The lifting hook requires regular inspections.

Figure 3.0: Lifting hooks, 4 main parts.

The clevis ears require the following inspections to be carried out daily:

|

Standard Size |

Maximum Permissible size |

Minimum Permissible Size |

Gap between Clevis ears (mm) |

18 |

17 |

16

|

Gap between Clevis ears (mm) |

22 |

23 |

20 |

Pin Hole flogging (mm) |

Ø 22

|

Ø 23.5

|

|

Lifting hooks exceeding the above stated allowances must be discarded and replaced.

The shaft requires visual inspection of its surface for cracking (specifically where it joins the body and shaft ears), gouging and deformation. If surface defects (previously stated) exceed 50% of surface then the part must be discarded and replaced.

These require inspection for cracking (particularly where they join the shaft) and gouging of the ears. No deformation of the shaft ears is tolerated but a wear allowance of 2mm is allowed. If the shaft ears do not conform to the wear allowance or have deformed then the lifting hook must be replaced.

Roll pins must be inspected for deformation of any type (out of roundness, gouging, bending along shaft, etc). If deformation exists in the roll pins then they should be replaced immediately.

This pin is not specified as lifting gear but must be inspected along with the lifting gear. The G pin must be free to rotate on the bearings in the top arm of the Sidelifter so that the Master/Oblong link that sits in the G pin groove does not rotate on the G pin shaft. Inspections of the G pin require the following:

If the G pin has bound up and does rotate freely and/or surface wear is seen on the G pin then the specified Steelbro service agent should be contacted. If circlip is damaged then immediate replacement is required.