Visual Check

Task

Firstly perform a visual check:

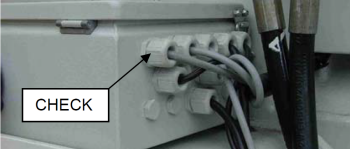

- Ensure that all junction box cable glands are tight,

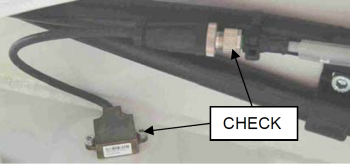

- Check all 8 angle sensors are securely fixed

- Check all angle sensor plug/socket assemblies are tight.

- Check Pressure Sensor Plug is tight

10 Jan 2009 PDF File |

SMARTLift |

Version 1 |

Author: |

The following procedure should be followed in addition to the normal pre-delivery Sidelifter check.

Visual Check |

Task |

|

Firstly perform a visual check:

|

|

VoltageCheck |

Task |

|

|

Using the Voltmeter Toggle Switch, check the voltage of the Main Battery and ECU Battery. If the ECU Battery reads less than 11.5v run the alternator to charge the battery. |

|

|

Stabiliser Extension Sensors |

Task |

|

|

Put the Sidelifter into Stabiliser Mode

|

|

|

||

Figure 2 |

Stabiliser Extension Sensors |

Task |

|

|

With the Stabiliser fully extended check the values are as per Figure 3.

Put the Stabiliser Foot on the ground and observe the change.

Repeat this for the Rear Crane. |

|

|

||

|

||

|

||

|

||

Figure 3 |

SB401 Angle Sensors Check |

Task |

Figure 4 |

For an SB401:

|

SB330 Angle Sensors Check |

Task |

Figure 5 |

For an SB330:

|

Angle Sensors Check |

Task |

Figure 6 |

|

Stabiliser Angle Sensor Calibration Check |

Task |

Figure 7 |

|

Bottom Arm Angle Sensor Calibration Check |

Task |

Figure 8 |

xxxx = contact STEELBRO |

Top Arm Angle Sensor Calibration Check |

Task |

Figure 9 |

xxxx = contact STEELBRO |