17 Aug 2004 PDF File |

Hydraulics |

Version 2 |

|

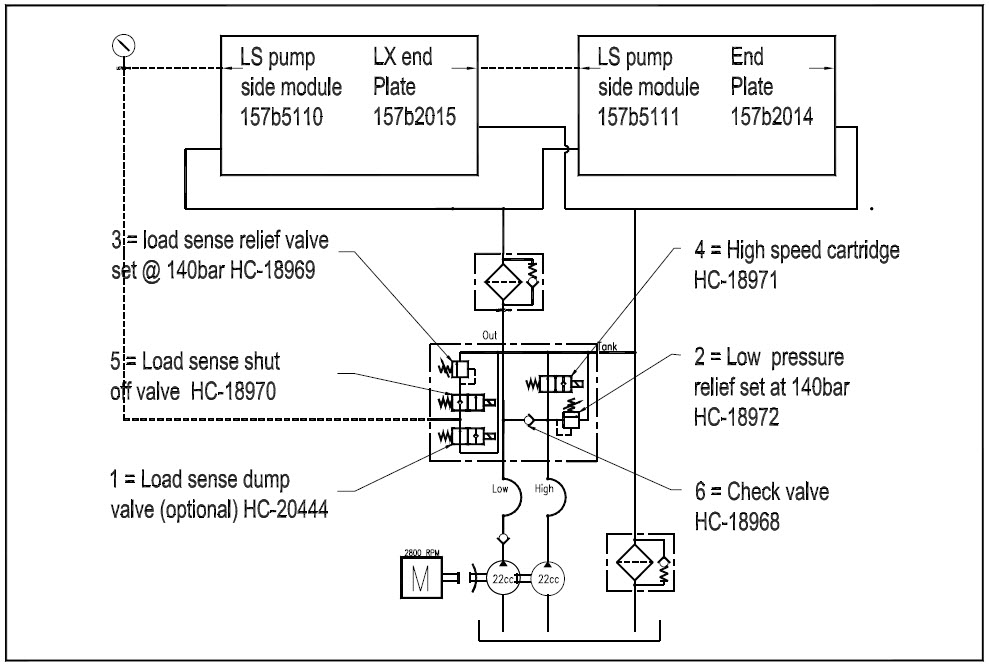

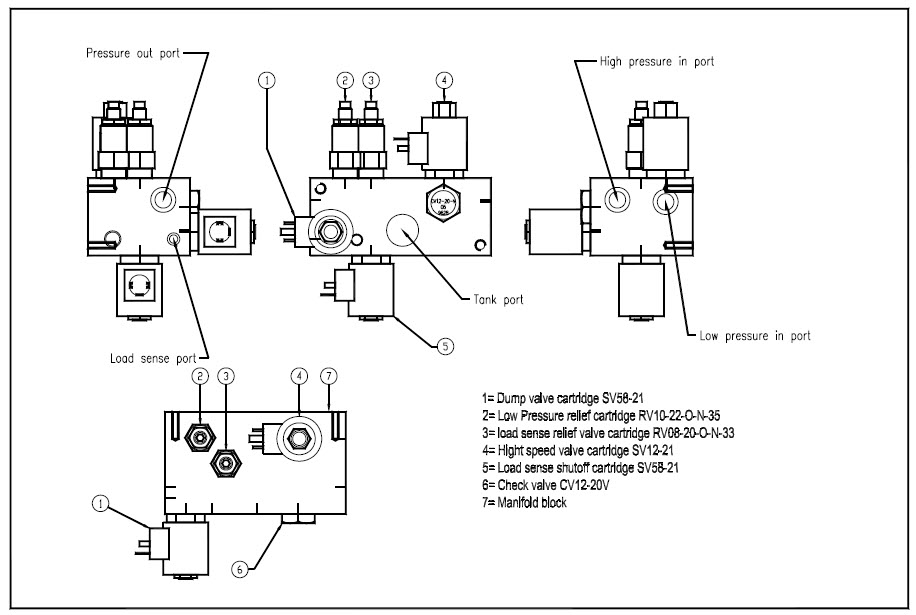

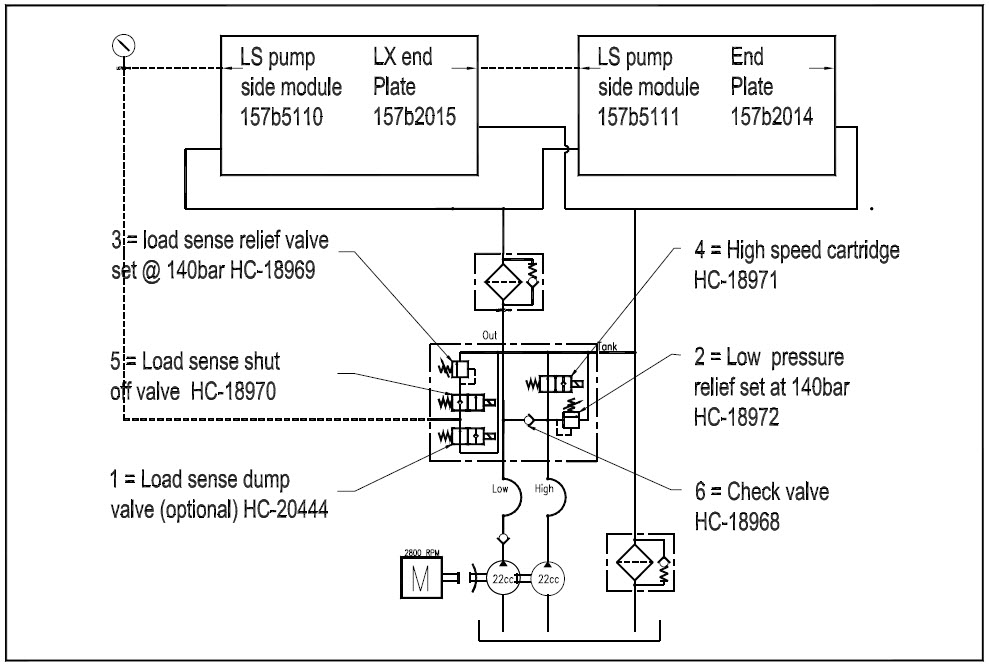

The tandem pump delivers oil to the high speed load sensed unloader valve, where the two flows can be

combined to give high speed operation, or split to give low speed with the second pump flow returning to

the oil reservoir..

In high speed the two oil flows are combined to give a total oil flow of 120l/m. To prevent the engine

from overload the working pressure is reduced to 140bar (2000psi).

The pressure limiting is done by opening valve (5) and allowing L/S pressure to be limited by relief valve

(3). Increased flow occurs when the high speed valve cartridge (4) is energised allowing the 2nd pump to enter

the circuit..

In low speed there is only one pump creating pressure (1st pump) with the 2nd pump being dumped to tank.

Total oil flow is now 60l/m at 280bar (4000psi).

The pressure is now being limited by the Danfoss PVG32 control valve, as the shutoff valve (5) is closed

preventing the relief valve (3) from operating. Oil is prevented from entering the 2nd pump circuit by

check valve (6).

Also fitted to this valve may be a solenoid operated dump valve that is activated by the joystick

controllers and the emergency stop buttons. This is an OPTION for higher levels of safety required for

dangerous goods CE machines and PTO Versions.

When the valve is in the de-energised condition load sensed (LS) oil is dumped to tank. When the valve is

energised the LS line is blocked to tank therefore allowing the hydraulic system to operate.

The low speed mode only applies to the lifting arms. The stabiliser legs are always in high speed

irrespective of the position of the high/low speed selector mode switch.

When the dump solenoid is de-energised it is fail safe to dump L/S pressure.

When the High speed valve (4) and shutoff valves (5) are de-energised they are set to low speed / high

pressure therefore allowing the operator to continue operation with heavy containers.

Following is a summary of the logic and function of the "High speed load sense unloader valve".

Speed Mode |

High speed |

Low Speed |

Operating oil flow |

120l/min |

60l/min |

Operating Pressure |

140bar (2000psi) @ valve(3) HS-LS-U valve |

280bar (4000psi) @ Danfoss PVG32 |

No of pumps operating |

2 x Pumps |

1 x Pump (second pump to tank) |

High speed Solenoid (4) |

Energised |

De-energised |

High Speed relief (2) |

140bar (2000psi) |

Not active |

Load Sense shutoff (5) |

Energised |

De-energised |

Load Sense Relief (3) |

140bar (2000psi) |

Not active |

EHF's |

Bypassed. (Not Active) |

Active |