S0023 Repair of Truck Mount Connector's Subframe-chassis

S0023 PDF File

|

Version 1

|

Structural

|

08-07-05

|

The following is a procedure for repairing the connectors between the subframe and chassis on a truck-mounted unit.

Removal of worn out/cracked connectors:

The removal of the connectors should be done one at a time to avoid the subframe slumping. The main things to watch out for are as follows:

- The part of the connector that is welded to the subframe, is to be removed without damaging the subframe.

- All welds on the subframe need to be ground flush.

Creating new connectors:

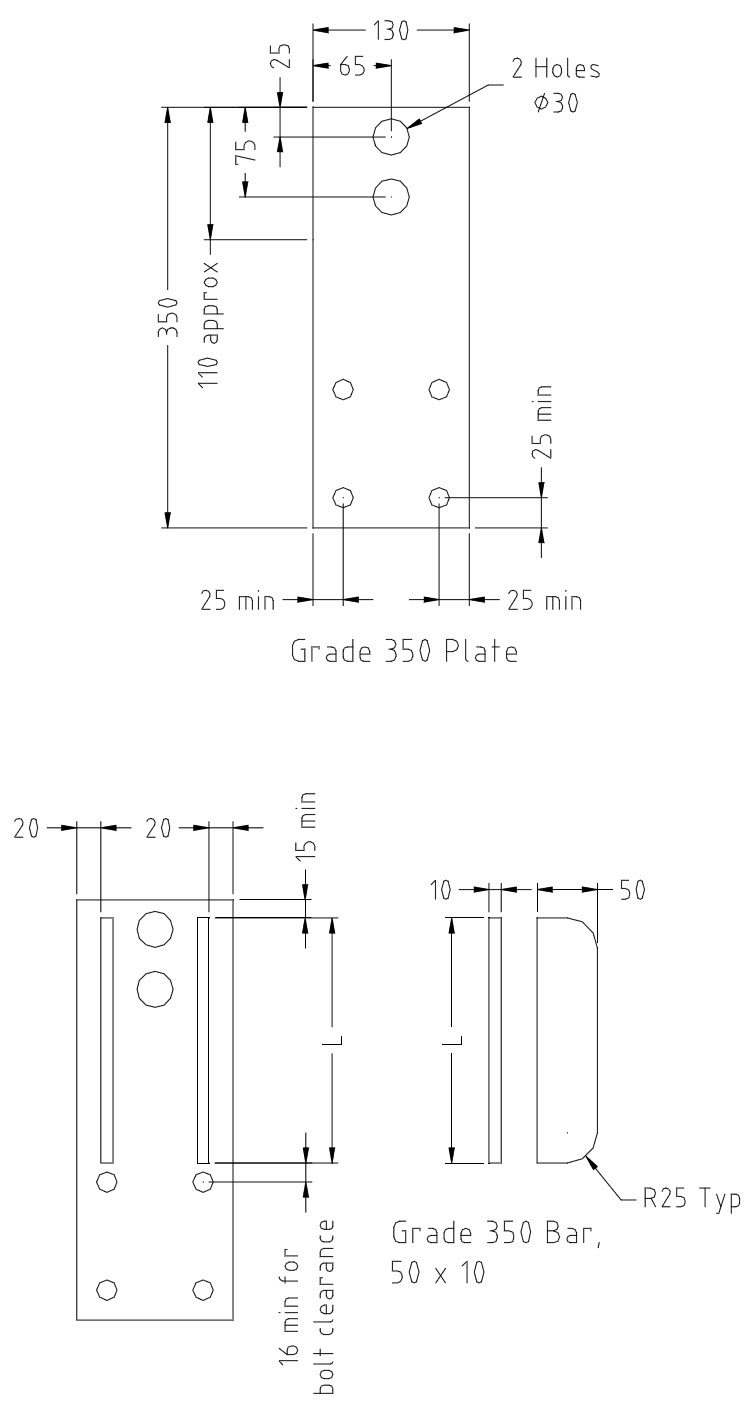

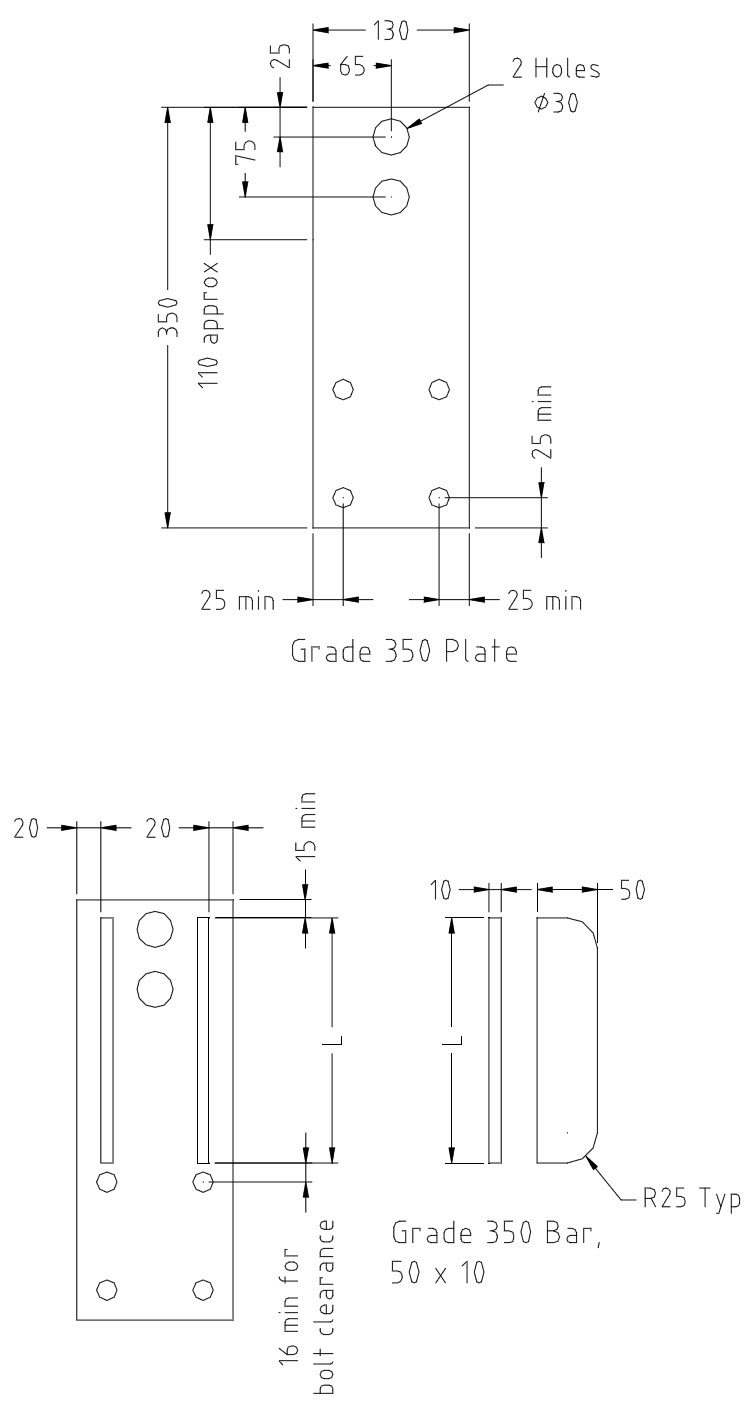

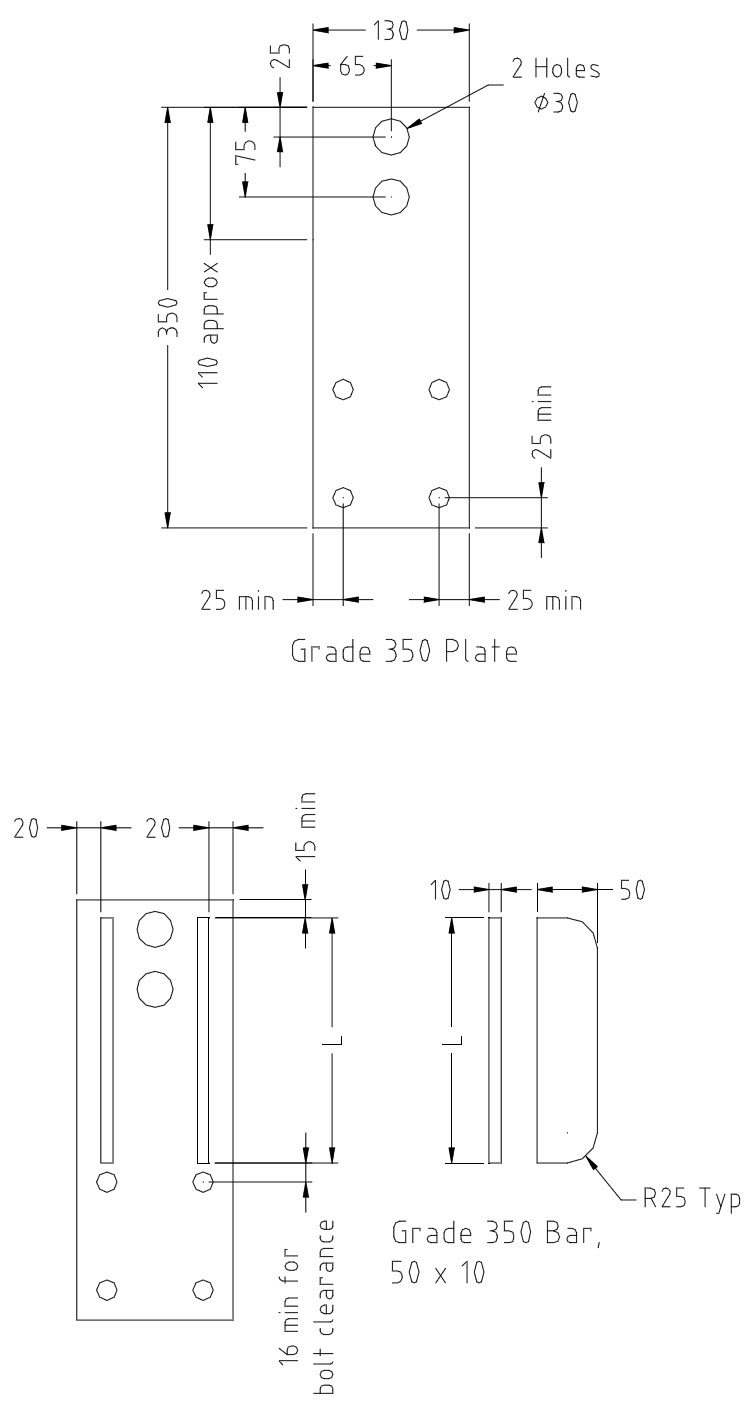

New connectors need to be made. These connectors are to be made out of Grade 350 flat plate 10mm and Grade 350 flat bar 50 x 10. If flat bar is not available use 10mm plate. The connectors need the following:

- 1 plate needs to be made and the plug weld holes need to be drilled/cut in these plates, as shown in figure 1. The bolt holes need to be drilled in this plate to match existing bolt holes, but must have the minimum dimensions from the edges that are shown in figure 1.

- The plate length can be longer than the 350mm shown in order to meet minimum dimension requirements.

- 2 pieces of grade 350 flat bar 50 x 10, (or Grade 350 10mm plate), need to be cut to the length L, shown in figure 1, derived from the minimum requirements and have the radii applied to them.

Fixing in place new connectors:

- Fix the connector to the chassis using the existing bolt holes. Do bolts up tight unless the pull the top half of the connector away from the subframe.

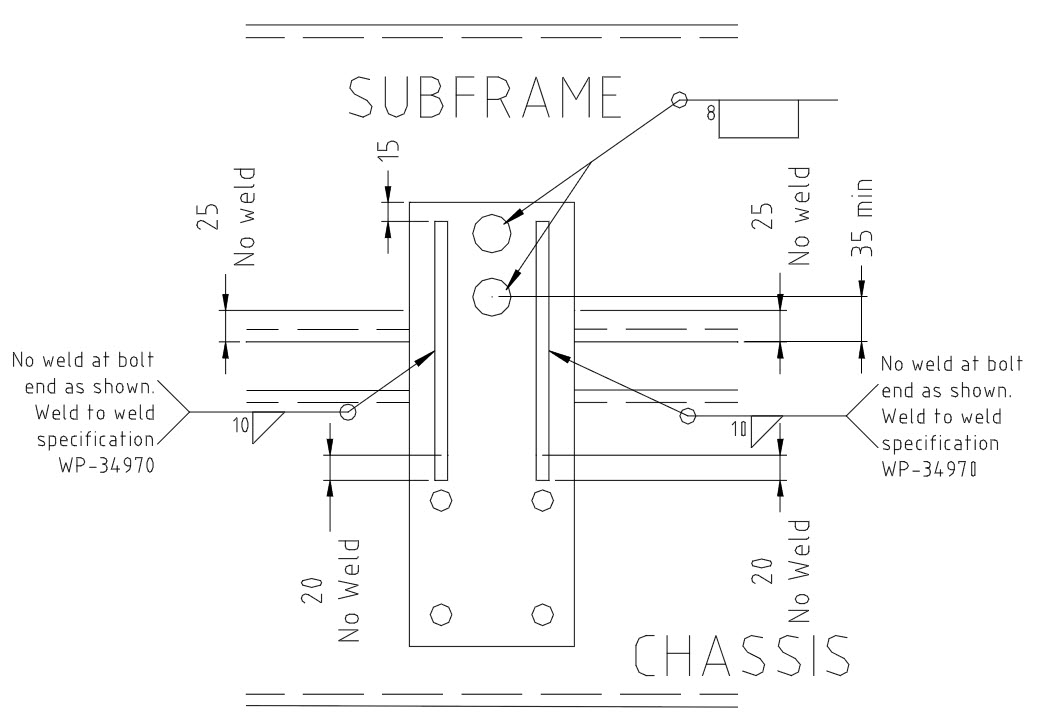

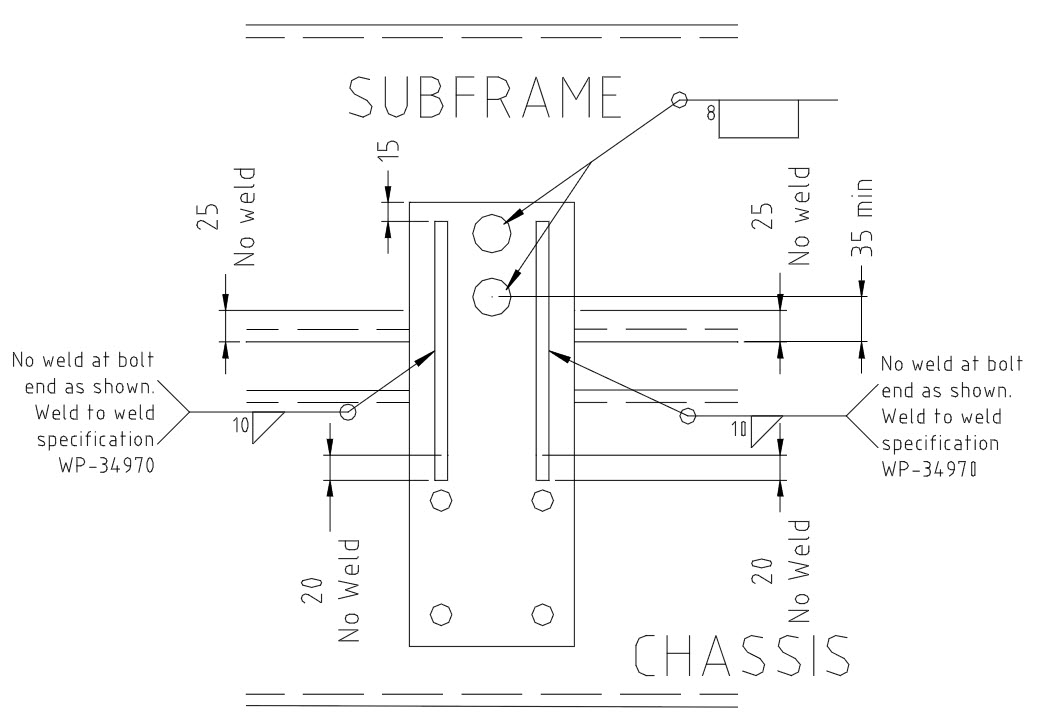

- Clamp top half of the connector hard up against subframe. Plug weld connector to subframe. Then weld around the connector, stopping the stated 25mm before the edge of the subframe as shown in figure 2. Weld all welds to weld specification WP-34970.

- Tack onto the connector plate the 2 pieces of 50 x 10 bar, to the dimensions shown in figure 2. Weld in place to weld specification WP-34970. Do not weld bar, within the 20mm of bolt hole show in figure 2.

Figure 1: Materials that need to be made for repair.

Figure 2: Requirements for fixing to subframe and chassis.