S0021 PDF File |

Version 1 |

Structural |

15-06-05 |

The following is a procedure for replacing the twistlock bodies on a SB360 crane base.

The removal of this part can be achieved in different ways depending on how damaged the twistlock body is. The main things to watch out for are as follows:

The plate that twistlock body sits on should not be damaged when removed. This is best achieved by grinding away all remaining weld between the twistlock body and the plate.

Do not damage the hole in the plate that the twistlock hole sits on. Do not try to pry the damaged twistlock body off with a bar from inside.

Make sure the surface of the plate that the twistlock body sits on is defect free and flat.

Avoid damage to any other part of the crane module.

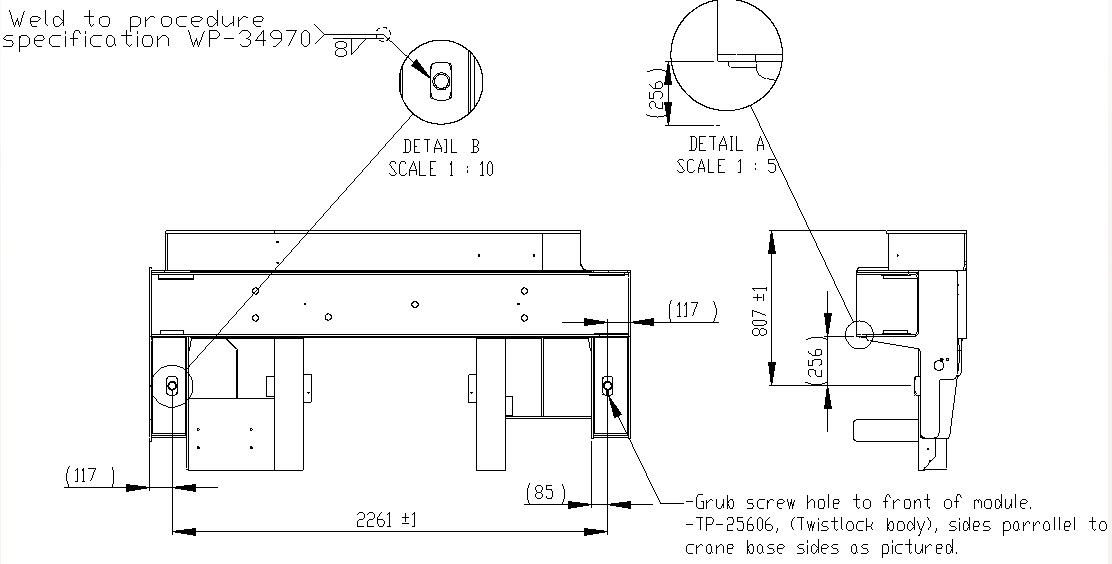

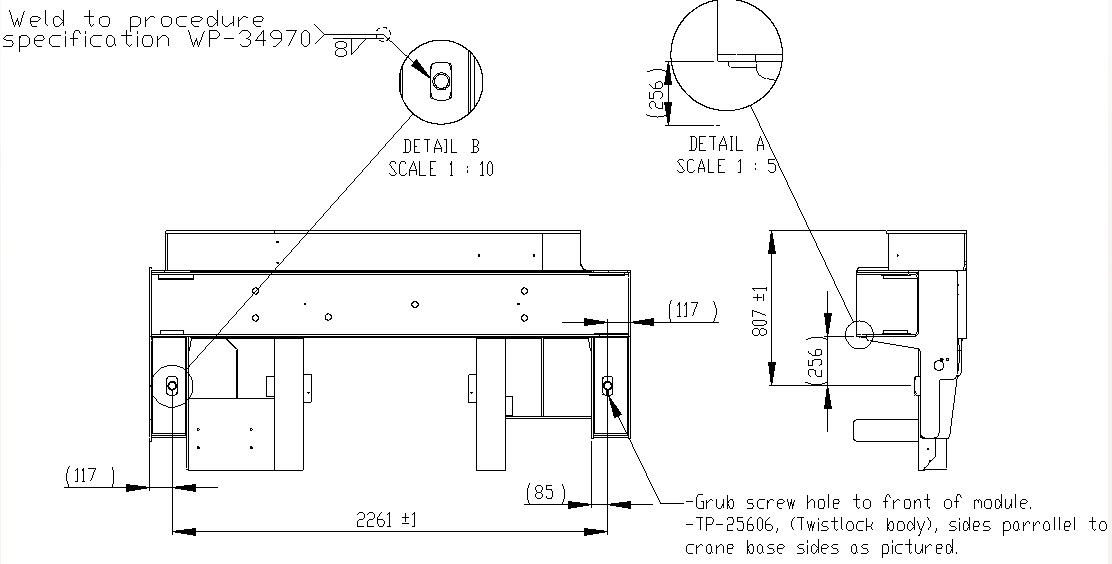

Tack into position the new twistlock bodies onto the crane base as shown in figure 1, taking into account the following points:

Use the toleranced dimensions to position the twistlock body. Use the reference dimensions, (dimensions in brackets) to run checks on the positioning. The reference dimensions can be out, by up to 4mm.

The hole in the plate should be concentric with the hole in the twistlock body.

Make sure the sides of the twistlock body are parallel with the sides of the crane base; otherwise the container will not fit nicely over the twistlock bodies.

Once tacked into position, check the dimension between the twistlock hole centres on the front and rear modules are the following:

In the 20' position, 5853mm ±6mm

In the 40' position, 11985mm ±6mm

Weld the twistlock bodies into position on the module plate using a 8mm fillet weld as shown in figure 1. The welding must be carried out to weld procedure specification WP-34970.

Once welded recheck 20' and 40' measurements stated above and also check width dimension of 2261mm ± 1.0mm.

Figure 1.0: Positioning of twistlock bodies on crane base.