S0011 PDF File |

Version 2 |

Structural |

17-08-04 |

When operating a Steelbro Crane Set, the stability of the crane is primarily governed by three factors:

These can each be affected by other factors, i.e. the deck height limits how far out the stabiliser foot can reach when placed on the ground; the suspension lash effects the contribution of un-sprung mass to the effective tare.

When the cranes are not fitted with offside stabiliser legs, positioning the load past the centre of the deck in the offside direction can lead to instability.

There are two extreme load conditions subject to the crane supports.

Figure 2 Sidelifter at max. height over deck

Figure 3 Sidelifter at max. reach

Model |

SB180 |

SB250 |

SB300 |

SB330 |

|||||||||||||||

|

Condition |

1 |

2 |

1 |

2 |

1 |

2 |

1 |

2 |

||||||||||

Force |

F1 |

65 kN |

172 kN |

91 kN |

239 kN |

109 kN |

287 kN |

120 kN |

316 kN |

||||||||||

F2 |

115 kN |

106 kN |

159 kN |

148 kN |

191 kN |

177 kN |

210 kN |

195 kN |

|||||||||||

F3 |

16 kN |

27 kN |

23 kN |

38 kN |

27 kN |

45 kN |

30 kN |

50 kN |

|||||||||||

F4 |

16 kN |

27 kN |

23 kN |

38 kN |

27 kN |

45 kN |

30 kN |

50 kN |

|||||||||||

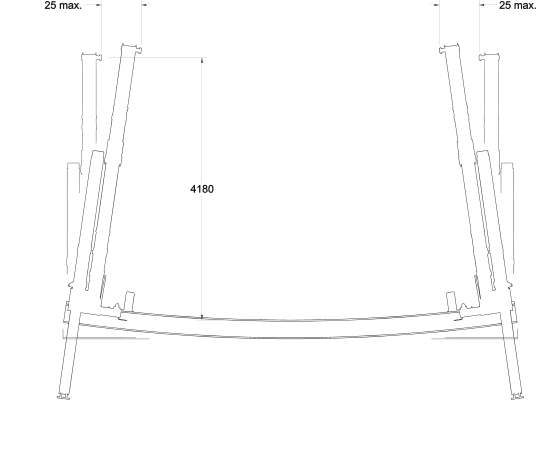

Figure 5 Maximum allowable deflections due to operating load

The design of the support frame or chassis is required to be stiff enough to prevent excessive deflection at the lifting pin (G Pin) on the crane. As long as the deflection at each crane due to the loads specified above, does not exceed 25mm at a height of 4180 above the support flange, then the correct operation of these units will be ensured.

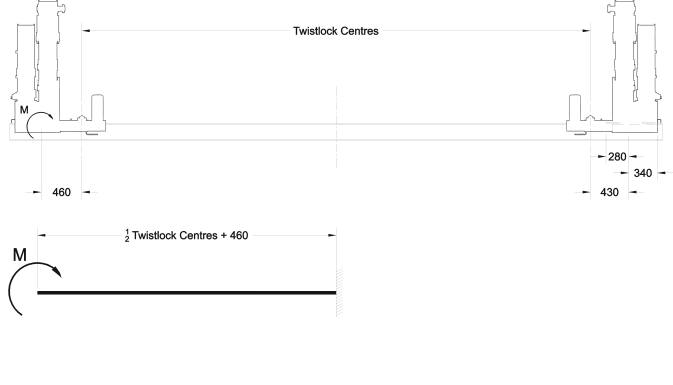

Figure 6 Free body diagram for typical truck chassis

The load distribution for a typical truck mount is as shown below:

The majority of truck manufacturers recommend that the sub-frame be attached to the chassis in such a way that the original bending and torsional characteristics of the vehicle are retained. This does create some conflict with the requirement for the two cranes to maintain alignment and minimise rolling of the chassis during the lifting process.

As the exact arrangement of supports will vary from installation to installation the following calculation has been carried out with assumptions i.e. consider the loads to be taken solely by one beam. The most critical aspect identified for proper crane operation is the amount of deflection allowed by the support frame/chassis. The following diagram considers only the opposing moment couples generated by the rolling of the cranes towards each other. From these we can determine the minimum chassis strength required to resist deflection if not taking axle supports into account.

Considering only one beam on the lift side of the truck to be resisting the moment couple, this will give a conservative stiffness requirement.

Model |

SB180 |

SB250 |

SB300 |

SB330 |

I (m4) |

44.3 x 10 - 6 |

61.9 x 10 - 6 |

74.0 x 10 - 6 |

81.5 x 10 - 6 |

Table 2 Recommended Minimum Area Moment of Inertia Values for 20 Foot Supporting Chassis

Figure 8. Sidelifter Mounting Details